|

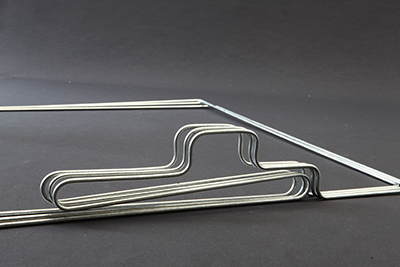

DOOR WARMER

Bundy Refrigeration supplies custom designed steel door warmers that provide an energy-efficient and cost effective solution for condensate elimination around door openings on Freezers and Fridge-Freezers. Door warmers can be supplied in Electricwelded Single Wall Tubing, according to customer requirements. A variety of coatings are available to meet various corrosion resistance needs.

| Raw Material |

| Tubing |

Electricwelded steel tube as per SAE J526 - Jan/2000 |

Standard size: Ø4,76mm ± 0,71mm WT (Ø 3/16'' x 0,28'')

Also available: Ø4,00mm: 6,35mm - 1/4'' |

| Coating |

Standard Hot Dipped Galvanized (HDG)

Corrosion resistance: 48-72 hrs depending on thickness*

Also available: Plain or Copper coated

Aluminized: up to 3000 hrs

*Hours before formation of red rust according to ASTM B117 salt spray resistance test. |

| Custom design specifications are available upon request. Please contact the sales department. |

|

|

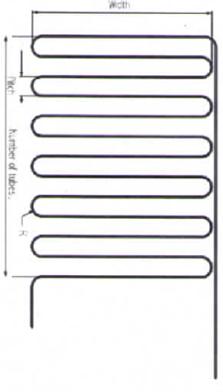

SKIN CONDENSER

A skin condenser is ideal for single door and two door refrigerator applications, as well as chest freezer applications when a “clean back” design is desired. These condensers are produced from plain or hot dip galvanized steel tubing that has been formed in a serpentine or other shape. Skin condenser are attached to one or more inside walls of the refrigerator case so that heat is transferred from the tubing through the exterior wall (skin) of the cabinet and to the surrounding atmosphere. |

CUSTOMIZED CONDENSER

|

| Raw Material |

| Tubing |

Electricwelded steel tube as per SAE J526 - Jan/2000 |

Standard: Ø4,76 ± 0,08 x 0,71 ± 0,13mm

Other sizes available |

| Finish |

Standard: Plain or Hot Dipped Galvanized (HDG) |

Resistance to red corrosion: 48 - 72 hrs depending on thickness*

*Hours before formation of red rust according to ASTM B117 salt spray test. |

| Custom design specifications are available upon request. Please contact the sales department. |

CUSTOMIZED CONDENSER

| Serpentine Radius (mm) |

Pitch (mm) |

Suggested Number of Tubes |

Maximum

Number of Tubes |

Suggested Width (mm) |

Maximum

Width (mm) |

| 25 |

50 |

5 to 17 |

27 |

250 to 530 |

600 |

| 30 |

60 |

5 to 14 |

23 |

250 to 530 |

600 |

| 45 |

90 |

5 to 11 |

13 |

250 to 420 |

800 |

| 50 |

100 |

3 to 5 |

7 |

250 to 1000 |

1200 |

|

|

|

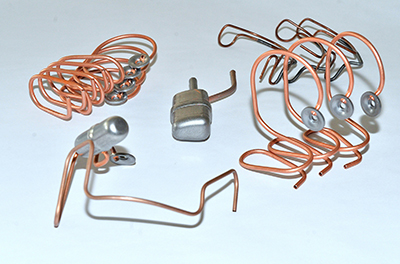

COMPRESSOR COMPONENTS

From cut-to-length tubing to completely formed and brazed assemblies Bundy Refrigeration works with the leading compressor manufacturers around the world to design, develop and supply tubular components and assemblies for compressor applications. Products are available in both Bundyweld™ double wall tubing and Electricwelded single wall steel tubing. The proven vibration and fatigue resistance of Bundyweld™ double wall tubing is ideal for compressor shock loops and discharge tubes, while Electricwelded single-wall tubing is a cost effective alternative for inlet and outlet connections. |

|